What is the difference between Self-Inking, Traditional Rubber and Pre-inked Stamps?

There several different types and brands of stamps - we hope this helps you to find the perfect one for you. Almost all our rubber stamps can be customised by adding logos, text or both. The three main types are all very popular and often the choice comes down to personal preference, but sometimes certain stamps are better for a particular job. For example the Traditional Rubber Stamps are available in larger sizes.

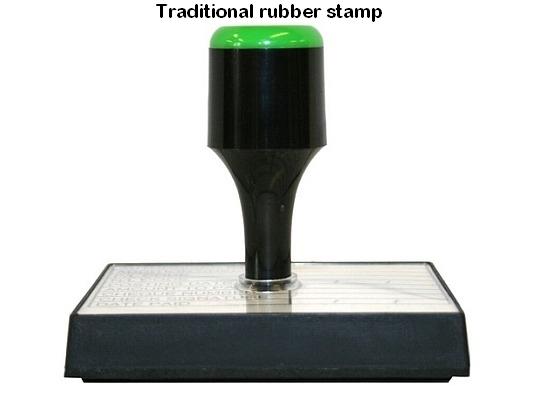

Our Traditional Rubber Stamps are usually a plastic mount and handle, with larger sizes provided on a wooden mount. They require a separate ink pad, the rubber stamp being pressed into the ink before each impression. Rubber Stamps are available in a wide range of sizes. On the website they can be ordered up to 150x75mm. But we can make larger ones if required.

Our very large stamps can have a rocker mount fitted which ensures an even impression can be achieved when stamping.

Please contact us with details if you would like a quote for a larger stamp.

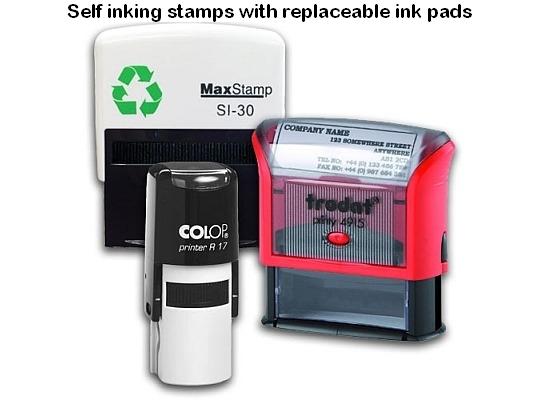

Self-Inking Stamps do not need a separate ink pad, as the ink is built into the stamp, the rubber die or stamp's impression rotates in and out of the ink pad when used. The die re-inks while sitting in the pad when not in use, this also keeps the ink pad air tight and the ink should be good for at least a couple of thousand impressions, often over many years.

The number of impressions per ink pad will depend on the type of paper used, how hard you press and the overall area being inked each time. When the pad runs dry simply replace the ink pad and the stamp is as good as new. We sell the three main brands of Self-Inking Stamps; MaxStamp, Trodat and Colop and they are available in both standard and heavy duty models.

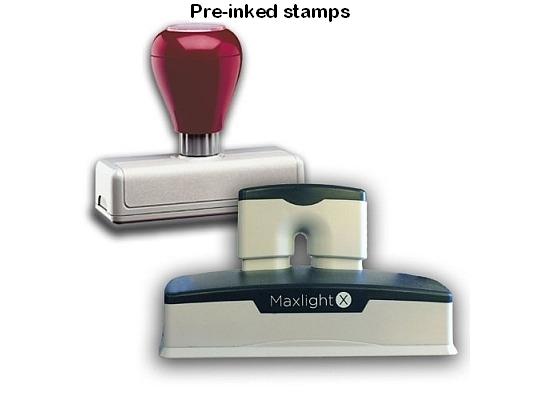

We have two ranges of pre-inked stamps; MaxLight flash stamps and our popular Perma pre-inked stamps. Both work in a similar way and provide high quality, crisp results for many thousands of impressions. In these the ink sits behind the impression and and flows through the die or membrane when the stamp is pressed. When these run dry they can be reinked with the appropriate reinking fluid.